-

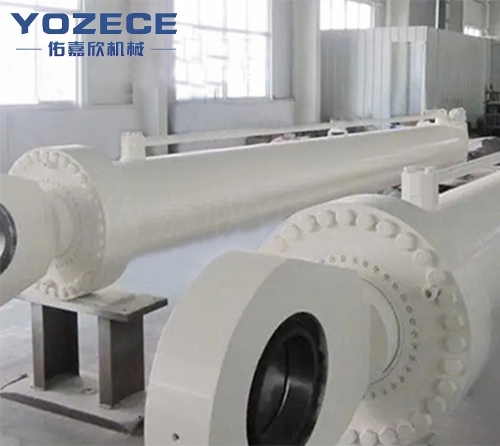

HSG Heavy Duty Engineering Hydraulic Cylinder

1.The product design complies with ISO6022 and DIN24333 specifications.

2.Maximum working pressure 250Kg1/cm².

3.Structure: the Front and back cover are connected to the flange plate by steel screws, flanges are screwed on cylinder body , which are tightly combined, easy to disassemble and repair.

4.It has the advantage of low friction and long service life.

5. Can Be used in engineering equipment, such as steel, metallurgy, shipping and other machinery.

6.Compatible with the CDH2 cylinder of Rexroth gmbh.

-

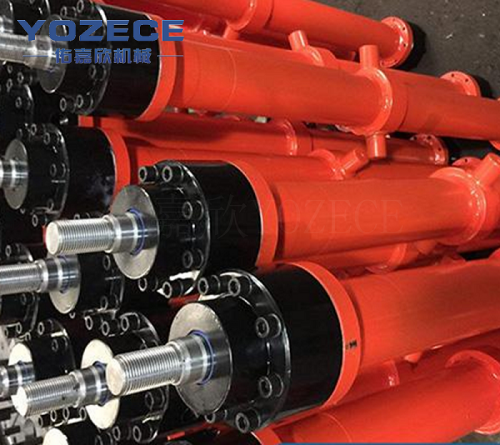

HSG Hydraulic Cylinders For Vehicle Mechanical Equipment

1.The product design complies with ISO6022 and DIN24333 specifications.

2.Maximum working pressure 250Kg1/cm².

3.Structure: the Front and back cover are connected to the flange plate by steel screws, flanges are screwed on cylinder body , which are tightly combined, easy to disassemble and repair.

4.It has the advantage of low friction and long service life.

5. Can Be used in engineering equipment, such as steel, metallurgy, shipping and other machinery.

6.Compatible with the CDH2 cylinder of Rexroth gmbh.

-

HSG Engineering Metallurgical Hydraulic Cylinder

1.The product design complies with ISO6022 and DIN24333 specifications.

2.Maximum working pressure 250Kg1/cm².

3.Structure: the Front and back cover are connected to the flange plate by steel screws, flanges are screwed on cylinder body , which are tightly combined, easy to disassemble and repair.

4.It has the advantage of low friction and long service life.

5. Can Be used in engineering equipment, such as steel, metallurgy, shipping and other machinery.

6.Compatible with the CDH2 cylinder of Rexroth gmbh.

-

Sanitation Sweeper Hydraulic Cylinder

1.The product design complies with ISO6022 and DIN24333 specifications.

2.Maximum working pressure 250Kg1/cm².

3.Structure: the Front and back cover are connected to the flange plate by steel screws, flanges are screwed on cylinder body , which are tightly combined, easy to disassemble and repair.

4.It has the advantage of low friction and long service life.

5. Can Be used in engineering equipment, such as steel, metallurgy, shipping and other machinery.

6.Compatible with the CDH2 cylinder of Rexroth gmbh.

-

Four-post Press Machine

1.Hydraulic system components are installed in bottom frame work, providing clean and tidy appearance

2.Floor-type structure, can withstand high pressure, easy for handing workpiece operation

3.Safe design, both hands operation, with emergency stop button and the top bottom mould calibration point for mold installation and calibration

4.Easy to adjust output , as long as the oil pressure adjustment, or setting the oil pressure, you can achieve the required pressure, simple and convenient

5.Optional accessories: Supporting Frame, grating, protective cover, pressure sensor, etc.

6.The verticality of the main shaft of the hydraulic cylinder and the working table surface can be controlled within 0.10mm

7.The parallelism between the hydraulic cylinder end and the worktable surface is controlled within0.10 mm

-

Four Pressure Gauge Hydraulic Systems

1.Low Noise:precise construction

2.Low Energy:Perfect oil design

3.Save space:Direct combination of pump and motor

4.Various kinds of machine:Multi-combination of oil way

5.Special machine type accept custom-made according to customer's requirement

-

Standard Hydraulic systems

1.Low Noise:precise construction

2.Low Energy:Perfect oil design

3.Save space:Direct combination of pump and motor

4.Various kinds of machine:Multi-combination of oil way

5.Special machine type accept custom-made according to customer's requirement

-

-

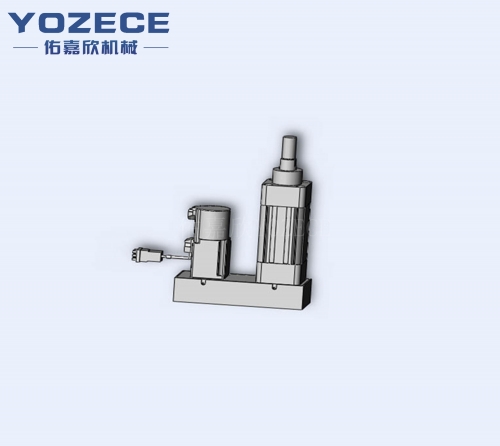

C-press Machine

1.Hydraulic system components are installed in bottom frame work, providing clean and tidy appearance

2.Floor-type structure, can withstand high pressure, easy for handing workpiece operation

3.Safe design, both hands operation, with emergency stop button and the top bottom mould calibration point for mold installation and calibration

4.Easy to adjust output , as long as the oil pressure adjustment, or setting the oil pressure, you can achieve the required pressure, simple and convenient

5.Optional accessories: Supporting Frame, grating, protective cover, pressure sensor, etc.

6.The verticality of the main shaft of the hydraulic cylinder and the working table surface can be controlled within 0.10mm

7.The parallelism between the hydraulic cylinder end and the worktable surface is controlled within0.10 mm

-

Hydraulic systems

1.Low Noise:precise construction

2.Low Energy:Perfect oil design

3.Save space:Direct combination of pump and motor

4.Various kinds of machine:Multi-combination of oil way

5.Special machine type accept custom-made according to customer's requirement

-

Head Trunnion Magnetic Stroke Adjustable Tie-Rod Hydraulic Cylinder

1.Trunnion Mounting: Head trunnion, intermediate trunnion ,rear trunnion opption

2.Operating pressure: medium duty 2000PSI (14 Mpa), heavy duty 3000PSI (21Mpa)

3.Tube: Cold drawn high impact stainless steel tube or carbon steel.

4.Rod: carbon steel, hard chrome plated and polished

5.Piston: Precision machined ductile iron (carbon steel or copper is option), provides high strength and an excellent bearing surface for extended cylinder life.

6.TIE RODS – Pre-stressed, high carbon steel tie rod construction eliminates axial loading of cylinder tube and maintains compression on tube

7.CUSHION – Precision machined cushion are available at either end and provide smooth deceleration, which helps reduce end of stroke shock.

8.Seals: highest quality configurations compatible

-

Intermediate Trunnion Magnetic Stroke Adjustable Tie-Rod Hydraulic Cylinder

1.Trunnion Mounting: Head trunnion, intermediate trunnion ,rear trunnion opption

2.Operating pressure: medium duty 2000PSI (14 Mpa), heavy duty 3000PSI (21Mpa)

3.Tube: Cold drawn high impact stainless steel tube or carbon steel.

4.Rod: carbon steel, hard chrome plated and polished

5.Piston: Precision machined ductile iron (carbon steel or copper is option), provides high strength and an excellent bearing surface for extended cylinder life.

6.TIE RODS – Pre-stressed, high carbon steel tie rod construction eliminates axial loading of cylinder tube and maintains compression on tube

7.CUSHION – Precision machined cushion are available at either end and provide smooth deceleration, which helps reduce end of stroke shock.

8.Seals: highest quality configurations compatible

Home

Home WhatsApp

WhatsApp Products

Products