Tie-rod hydraulic cylinders have four rods (bolts) that connect the ends of a double-acting hydraulic cylinder to add strength and stability to the cylinder and prevent it from coming apart under pressure. Double-acting tie-rod hydraulic cylinders provide power in both directions (extending and retracting), which allows for more precise movement. They have a linear actuator and are used in agricultural equipment, industrial machinery, and construction equipment to support, lift, and press heavy loads.

-

Head Flange Magnetic Double Rod Tie-Rod Hydraulic Cylinder

1.Trunnion Mounting: Head trunnion, intermediate trunnion ,rear trunnion opption

2.Operating pressure: medium duty 2000PSI (14 Mpa), heavy duty 3000PSI (21Mpa)

3.Tube: Cold drawn high impact stainless steel tube or carbon steel.

4.Rod: carbon steel, hard chrome plated and polished

5.Piston: Precision machined ductile iron (carbon steel or copper is option), provides high strength and an excellent bearing surface for extended cylinder life.

6.TIE RODS – Pre-stressed, high carbon steel tie rod construction eliminates axial loading of cylinder tube and maintains compression on tube

7.CUSHION – Precision machined cushion are available at either end and provide smooth deceleration, which helps reduce end of stroke shock.

8.Seals: highest quality configurations compatible

-

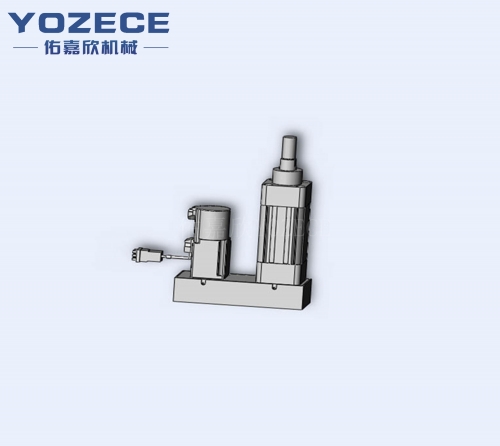

Standard Magnetic Double Rod Tie-rod Hydraulic Cylinder

1.Trunnion Mounting: Head trunnion, intermediate trunnion ,rear trunnion opption

2.Operating pressure: medium duty 2000PSI (14 Mpa), heavy duty 3000PSI (21Mpa)

3.Tube: Cold drawn high impact stainless steel tube or carbon steel.

4.Rod: carbon steel, hard chrome plated and polished

5.Piston: Precision machined ductile iron (carbon steel or copper is option), provides high strength and an excellent bearing surface for extended cylinder life.

6.TIE RODS – Pre-stressed, high carbon steel tie rod construction eliminates axial loading of cylinder tube and maintains compression on tube

7.CUSHION – Precision machined cushion are available at either end and provide smooth deceleration, which helps reduce end of stroke shock.

8.Seals: highest quality configurations compatible

-

Clevis Bracket Magnetic Tie-Rod Hydraulic Cylinder

1.Trunnion Mounting: Head trunnion, intermediate trunnion ,rear trunnion opption

2.Operating pressure: medium duty 2000PSI (14 Mpa), heavy duty 3000PSI (21Mpa)

3.Tube: Cold drawn high impact stainless steel tube or carbon steel.

4.Rod: carbon steel, hard chrome plated and polished

5.Piston: Precision machined ductile iron (carbon steel or copper is option), provides high strength and an excellent bearing surface for extended cylinder life.

6.TIE RODS – Pre-stressed, high carbon steel tie rod construction eliminates axial loading of cylinder tube and maintains compression on tube

7.CUSHION – Precision machined cushion are available at either end and provide smooth deceleration, which helps reduce end of stroke shock.

8.Seals: highest quality configurations compatible

-

Eye Bracket Magnetic Tie-Rod Hydraulic Cylinder

1.Trunnion Mounting: Head trunnion, intermediate trunnion ,rear trunnion opption

2.Operating pressure: medium duty 2000PSI (14 Mpa), heavy duty 3000PSI (21Mpa)

3.Tube: Cold drawn high impact stainless steel tube or carbon steel.

4.Rod: carbon steel, hard chrome plated and polished

5.Piston: Precision machined ductile iron (carbon steel or copper is option), provides high strength and an excellent bearing surface for extended cylinder life.

6.TIE RODS – Pre-stressed, high carbon steel tie rod construction eliminates axial loading of cylinder tube and maintains compression on tube

7.CUSHION – Precision machined cushion are available at either end and provide smooth deceleration, which helps reduce end of stroke shock.

8.Seals: highest quality configurations compatible

-

Head Turnnion Magnetic Tie-Rod Hydraulic Cylinder

1.Trunnion Mounting: Head trunnion, intermediate trunnion ,rear trunnion opption

2.Operating pressure: medium duty 2000PSI (14 Mpa), heavy duty 3000PSI (21Mpa)

3.Tube: Cold drawn high impact stainless steel tube or carbon steel.

4.Rod: carbon steel, hard chrome plated and polished

5.Piston: Precision machined ductile iron (carbon steel or copper is option), provides high strength and an excellent bearing surface for extended cylinder life.

6.TIE RODS – Pre-stressed, high carbon steel tie rod construction eliminates axial loading of cylinder tube and maintains compression on tube

7.CUSHION – Precision machined cushion are available at either end and provide smooth deceleration, which helps reduce end of stroke shock.

8.Seals: highest quality configurations compatible

-

Intermediate Trunnion Magnetic Tie-Rod Hydraulic Cylinder

1.Trunnion Mounting: Head trunnion, intermediate trunnion ,rear trunnion opption

2.Operating pressure: medium duty 2000PSI (14 Mpa), heavy duty 3000PSI (21Mpa)

3.Tube: Cold drawn high impact stainless steel tube or carbon steel.

4.Rod: carbon steel, hard chrome plated and polished

5.Piston: Precision machined ductile iron (carbon steel or copper is option), provides high strength and an excellent bearing surface for extended cylinder life.

6.TIE RODS – Pre-stressed, high carbon steel tie rod construction eliminates axial loading of cylinder tube and maintains compression on tube

7.CUSHION – Precision machined cushion are available at either end and provide smooth deceleration, which helps reduce end of stroke shock.

8.Seals: highest quality configurations compatible

-

End Foot Magnetic Tie-Rod Hydraulic Cylinder

1.Trunnion Mounting: Head trunnion, intermediate trunnion ,rear trunnion opption

2.Operating pressure: medium duty 2000PSI (14 Mpa), heavy duty 3000PSI (21Mpa)

3.Tube: Cold drawn high impact stainless steel tube or carbon steel.

4.Rod: carbon steel, hard chrome plated and polished

5.Piston: Precision machined ductile iron (carbon steel or copper is option), provides high strength and an excellent bearing surface for extended cylinder life.

6.TIE RODS – Pre-stressed, high carbon steel tie rod construction eliminates axial loading of cylinder tube and maintains compression on tube

7.CUSHION – Precision machined cushion are available at either end and provide smooth deceleration, which helps reduce end of stroke shock.

8.Seals: highest quality configurations compatible

-

Side Foot Magnetic Tie-Rod Hydraulic Cylindder

1.Trunnion Mounting: Head trunnion, intermediate trunnion ,rear trunnion opption

2.Operating pressure: medium duty 2000PSI (14 Mpa), heavy duty 3000PSI (21Mpa)

3.Tube: Cold drawn high impact stainless steel tube or carbon steel.

4.Rod: carbon steel, hard chrome plated and polished

5.Piston: Precision machined ductile iron (carbon steel or copper is option), provides high strength and an excellent bearing surface for extended cylinder life.

6.TIE RODS – Pre-stressed, high carbon steel tie rod construction eliminates axial loading of cylinder tube and maintains compression on tube

7.CUSHION – Precision machined cushion are available at either end and provide smooth deceleration, which helps reduce end of stroke shock.

8.Seals: highest quality configurations compatible

-

Rear Flange Magnetic Tir-Rod Hydraulic Cylinder

1.Trunnion Mounting: Head trunnion, intermediate trunnion ,rear trunnion opption

2.Operating pressure: medium duty 2000PSI (14 Mpa), heavy duty 3000PSI (21Mpa)

3.Tube: Cold drawn high impact stainless steel tube or carbon steel.

4.Rod: carbon steel, hard chrome plated and polished

5.Piston: Precision machined ductile iron (carbon steel or copper is option), provides high strength and an excellent bearing surface for extended cylinder life.

6.TIE RODS – Pre-stressed, high carbon steel tie rod construction eliminates axial loading of cylinder tube and maintains compression on tube

7.CUSHION – Precision machined cushion are available at either end and provide smooth deceleration, which helps reduce end of stroke shock.

8.Seals: highest quality configurations compatible

-

Head Flange Magnetic Tie-Rod Hydraulic Cylinder

1.Trunnion Mounting: Head trunnion, intermediate trunnion ,rear trunnion opption

2.Operating pressure: medium duty 2000PSI (14 Mpa), heavy duty 3000PSI (21Mpa)

3.Tube: Cold drawn high impact stainless steel tube or carbon steel.

4.Rod: carbon steel, hard chrome plated and polished

5.Piston: Precision machined ductile iron (carbon steel or copper is option), provides high strength and an excellent bearing surface for extended cylinder life.

6.TIE RODS – Pre-stressed, high carbon steel tie rod construction eliminates axial loading of cylinder tube and maintains compression on tube

7.CUSHION – Precision machined cushion are available at either end and provide smooth deceleration, which helps reduce end of stroke shock.

8.Seals: highest quality configurations compatible

-

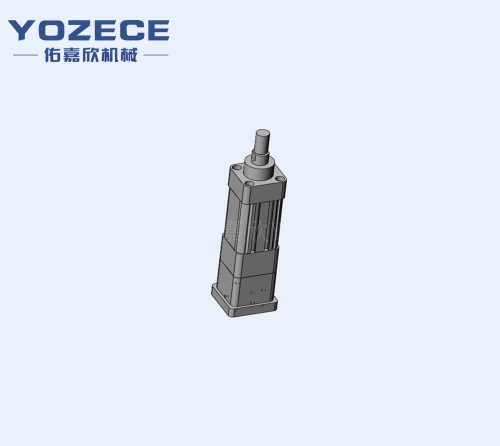

Standard Magnetic Tie-Rod Hydraulic Cylinder

1.Trunnion Mounting: Head trunnion, intermediate trunnion ,rear trunnion opption

2.Operating pressure: medium duty 2000PSI (14 Mpa), heavy duty 3000PSI (21Mpa)

3.Tube: Cold drawn high impact stainless steel tube or carbon steel.

4.Rod: carbon steel, hard chrome plated and polished

5.Piston: Precision machined ductile iron (carbon steel or copper is option), provides high strength and an excellent bearing surface for extended cylinder life.

6.TIE RODS – Pre-stressed, high carbon steel tie rod construction eliminates axial loading of cylinder tube and maintains compression on tube

7.CUSHION – Precision machined cushion are available at either end and provide smooth deceleration, which helps reduce end of stroke shock.

8.Seals: highest quality configurations compatible

-

Head Trunnion Stroke Adjustable Tie-Rod Hydraulic Cylinder

1.Trunnion Mounting: Head trunnion, intermediate trunnion ,rear trunnion opption

2.Operating pressure: medium duty 2000PSI (14 Mpa), heavy duty 3000PSI (21Mpa)

3.Tube: Cold drawn high impact stainless steel tube or carbon steel.

4.Rod: carbon steel, hard chrome plated and polished

5.Piston: Precision machined ductile iron (carbon steel or copper is option), provides high strength and an excellent bearing surface for extended cylinder life.

6.TIE RODS – Pre-stressed, high carbon steel tie rod construction eliminates axial loading of cylinder tube and maintains compression on tube

7.CUSHION – Precision machined cushion are available at either end and provide smooth deceleration, which helps reduce end of stroke shock.

8.Seals: highest quality configurations compatible

Home

Home WhatsApp

WhatsApp Products

Products