Production Parameters

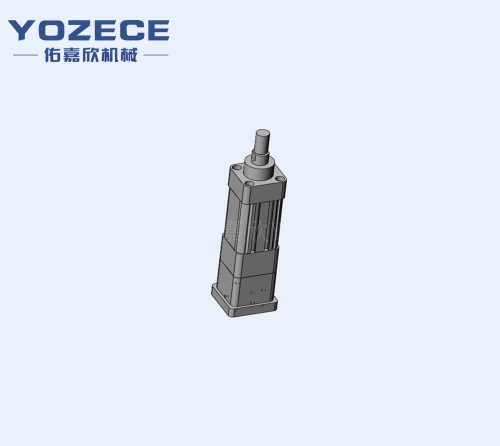

| Bore | 25-125mm |

| Stroke | 5-100mm |

| Working pressure | up to 500bar |

| Material | aluminum or Steel |

| Operating temperature | -20ºC to 200 ºC |

| Seak kits | Hallite ,Trelleborg,Parke |

Company Profile

Kunshan Youjiaxin Machinery Equipment Co., Ltd. (abbreviated as YOZECE) was established in 2006 and is located in Jiangsu, China. In 2021, the company invested $4.5 million to establish Youjiaxin Hydraulic Technology (Dongtai) Co., Ltd. The new factory, located in Yancheng, covers an area of 200 acres with a building area of 12,000 square meters. In 2022, our sales revenue exceeded $12 million.

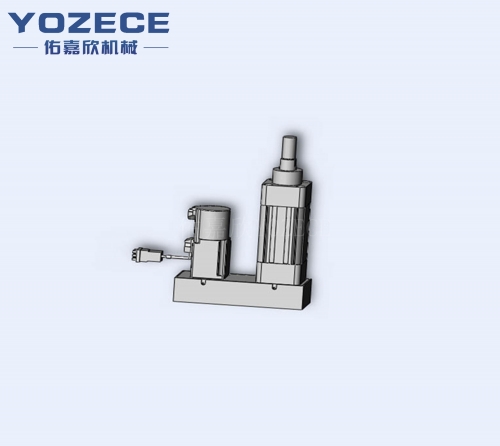

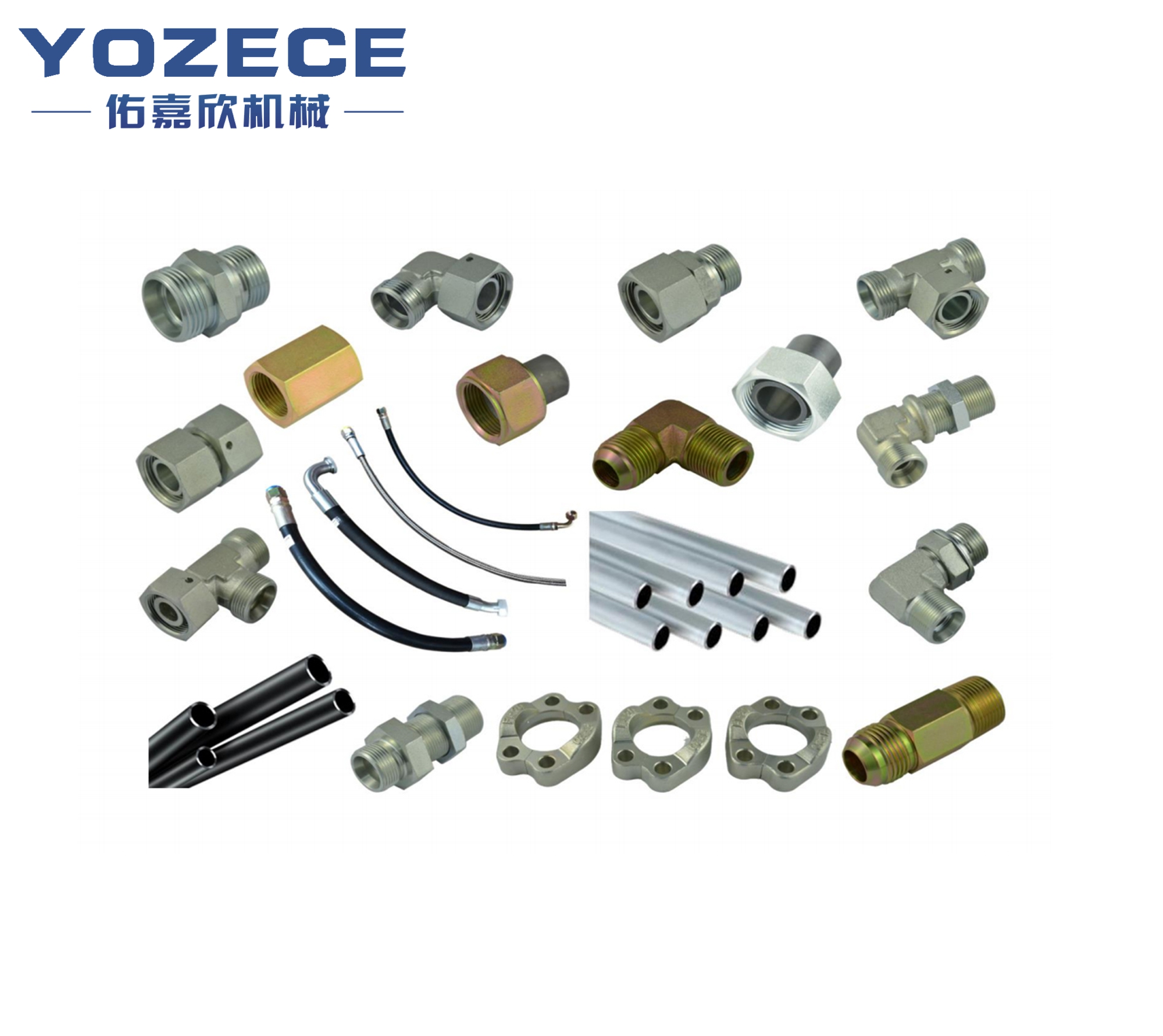

Youjiaxin Machinery specializes in the manufacturing of equipment centered around "power transmission systems." Our main products include precision tool cylinders, engineering machinery cylinders, gas-liquid booster cylinders, and presses. We focus on the research and production of hydraulic, pneumatic, and air-oil conversion power transmission systems to provide high-performance and reliable products to our customers.

The company employs 153 industry professionals and has 20 years of experience in research and manufacturing. Our technical team is led by multiple PhDs and industry experts, holding 38 independent patents. We have established long-term technical cooperation with universities and research institutes. Youjiaxin's products are known for their long lifespan, high precision, high output, compact size, and leak-proof characteristics, and are widely used in mining equipment, engineering machinery, mold industries, and automation sectors.

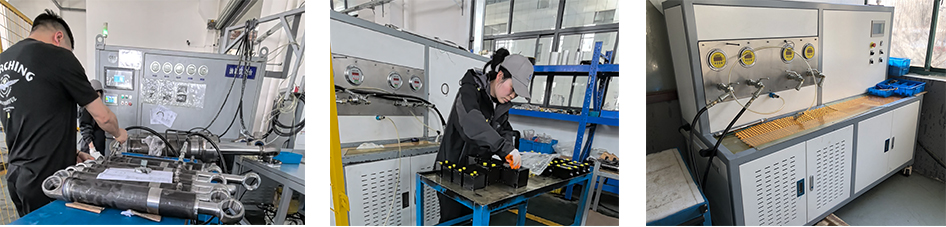

Quality Inspection Equipment

We have our own laboratory in the factory to inspect and test the entire processing procedure:

Raw Material Inspection: Verify the material and dimensions, and use microscopes and Vickers hardness testers to check the metallography and hardness of the materials.

Parts Inspection: Use CMM and gauge rods to check the specifications and threads of the parts.

Weld Seam Inspection: Use ultrasonic flaw detectors to check weld seam defects and ensure sealing.

Cylinder Performance Testing: Use cylinder test benches to test cylinder performance and oil particle counters to measure oil quality.

Paint Inspection: Use coating thickness gauges and cross-cut testers to check the paint thickness and adhesion. All test results are recorded and quality inspection reports are provided.

Welding

Our welding process includes:

Visual Inspection: Check the weld seam appearance to ensure it meets standard requirements.

Mechanical Property Testing: Evaluate the strength, ductility, and toughness of the welded parts.

X-ray Inspection: Ensure there are no internal gaps.

Ultrasonic and Magnetic Particle Testing: Further check the quality of the welds.

Test Bench

We use Hallite ,Trelleborg,Parker brand seals and offer a one-year warranty for our cylinders. Each cylinder undergoes weld seam inspection, leak detection, and pressure testing after assembly to ensure quality and performance meet design requirements. Additionally, we engrave part numbers and production dates on our products for tracking and after-sales service.

Painting

We have a semi-automated painting line. Before painting, we perform sandblasting to remove surface scale and rust, increasing the adhesion strength between the coating and the substrate. After electrostatic dust removal, the products are transported to the painting room via a conveyor belt, where robotic arms apply the paint evenly. We are capable of marine-grade painting, ensuring that the coatings are highly resistant to corrosion and durable.

After painting, the products undergo drying and cooling, followed by tests for hardness, thickness, and adhesion to ensure the painting quality. All test results are recorded in the OQC report, which is printed and attached to the packaging box, accompanying the products to the customer.

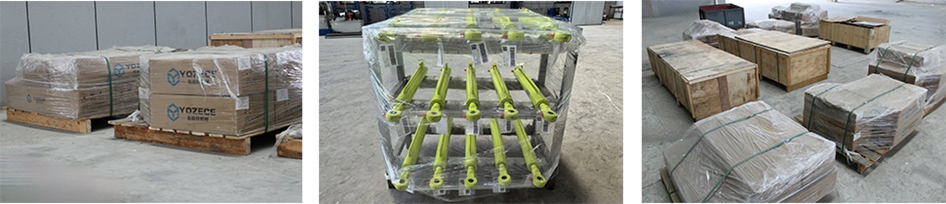

Packaging&Shipping

Before shipping, we check for any surface cracks or collision marks on the cylinders, ensure protective sealing plates on all oil ports, verify the condition of the oil port threads, and re-tighten all fastening bolts. Each cylinder is labeled with detailed information, including bore diameter, stroke, and working pressure. We use individual plastic bags, cardboard boxes, and wooden crates for packaging, along with plastic film and foam pads for protection. After shipping, we send packing pictures to the customers to ensure all goods have been properly loaded in China.

Home

Home WhatsApp

WhatsApp Products

Products